Not the normal car boot contents I thought (with raised eyebrows) and, at Norman's invitation, went to have a look.

Although 7109 is a 12 inch to the foot scale, I've long admired the amazing amount of time and effort that goes into model locos. This was another moment of admiration.

|

| Car boot contents (1) |

|

| Car boot contents (2) |

|

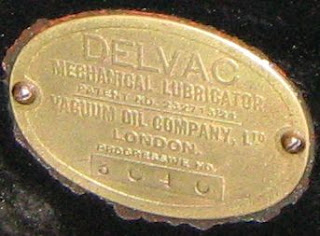

| Amazing detail (and not just the boot catch!) |

|

| Right hand side |

|

| Nearing completion (June 2011) |

|

| Sentinel 8805 (Photo Tony Thomas) |

|

| And again (Photo Tony Thomas) |