Tuesday 23rd February 2016 was an important day - the day an inspector called. In this case Peter Hawkins the boiler inspector.

It had been a busy few weeks leading up to this but essential to be ready for action on the S&D 50th anniversary of the line closure on March 6th 1966.

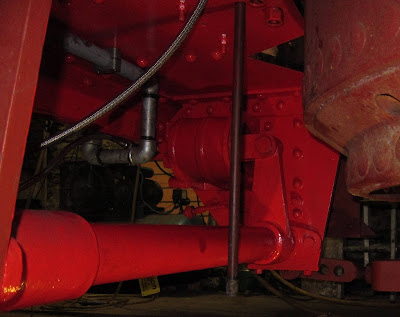

There were various tests: A general inspection of paperwork covering materials used, certificates of conformity and calibration; a hydraulic test to 1.5x working pressure (412.5 psi) to check boiler fittings were attached properly; a maxed-out steam accumulation test to abuse the boiler and check the safety valves could cope; a test of the ability to keep the boiler filled with water under maximum output conditions.

|

| Giving the clouds a shock! |

If you are wondering what Sentinel 7109 sounds like when being steam tested, try this video clip: (

Higher def. on YouTube)

We also tried a less formal haulage test on the 1 in 53 gradient as in the following video clip (

Higher def. on YouTube):

There are interesting times ahead!

(And it passed the tests too!).