|

| Highlighted original oil pot and down-pipe with wipe-rag |

The oil pot was another example from Joyce's missing items portfolio so I had to construct a new one. I used the end section of a small argon gas cylinder and added a valve to turn the flow on and off.

These items are hidden in the photo below beneath an upturned metal cover (OK, it's a bean can but it was a perfect fit!). The down-pipe is original but the new rag was a hem extracted from an old pair of jeans.

|

| Gravity-fed oil feed |

Being driven by the engines, the mechanical lubricator was an ideal candidate but its four pump barrels were already allocated.

|

| Mechanical Lubricator (before restoration) |

|

| Drip trays and drip feed tubes |

In the back of my mind has always been the thought that 7109 was a prototype and thus some parts/methods of operation were possibly experimental and not well tried and tested; they could thus be improved.

|

| Oil from the gear bearings into the drip tray |

A number of parts needed to be made:

1. An adaptor to connect a pipe to the lubricator pump.

2. The pipe itself (I chose to cheat and use rubber fuel hose).

3. The three-drip device.

4. Rigid support for the feeder so it wouldn't shake it all about.

The adaptor seemed an easy task: it would be needing BSP threads obviously? No it wouldn't! To cut a long story short, it needed a rare British Standard Cycle thread as used on push-bikes and motor bikes. The thread was actually 3/4" 20tpi and taps and dies were surprisingly easy to obtain (Ebay).

|

| The rubber hose adaptor rightmost |

|

| Three-drip device |

Any resemblance in the body of the device to a Lidl compressed-air adaptor are purely coincidence of course (but it saved a lot of work for very little cost!).

|

| The dripper attached to an angle-iron support |

|

| The complete dripper support |

|

| Pipe clamped to the water tank |

|

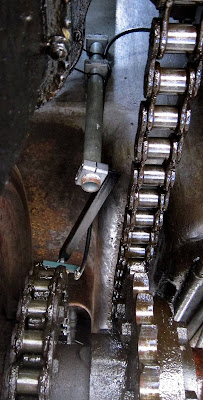

| Viewed from underneath |

|

| Not an easy photo so take (apologies for low quality) |

|

| Rubber pipe routing |

One question I don't have the answer to is how much oil does a chain need? I haven't oiled my mountain bike's chain for years and it is still happy; however, these chains work a little harder than my bike's so sufficient will be enough.

I'm also hoping to reduce the oil consumption. 7109 uses about 3 pints of cylinder oil a day - that seems a lot to me.

I'll remove the old gravity-feed oiler when all is set up satisfactorily.