In June 2013, I wrote extensively about the construction of an elaborate plug valve with a hidden secret. It was originally fitted in 1928 so was a historical gem.

|

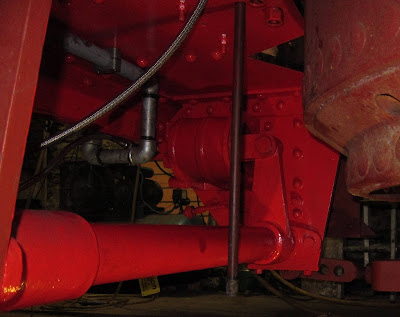

| Plug valve in water feed line. |

|

| Split top bit |

|

| Split plug |

There was a disadvantage with this in that to clear the strainer by removing the plug from the end of the 'T', the tank had to be emptied to avoid a personal irrigation. So the valve should have been upstream of the strainer!

I've resorted to modern parts to rebuild the valve and strainer with the disadvantage removed.

|

| Ball valve and 'Y' strainer |

I'll tidy up the appearance in due course [as below].

|

| With a lick of paint... |

|

| ...And some frost protection where the pipe can't be drained |