|

| Leaking roof! |

|

| Roof support girder before detachment from the old roof |

| 7109 playing in the snow boxing day 2010 |

|

| Leaking roof! |

|

| Roof support girder before detachment from the old roof |

| 7109 playing in the snow boxing day 2010 |

|

| At 83, young Joyce playing in the snow on Boxing Day 2010 (I must make some Xmas cards with this photo for next year) |

|

| Inspection bolt with blind axial hole and linked radial aperture for oil level checking |

|

| The bolt is partly removed to check if oil comes out of the radial aperture |

|

| View from above |

|

| Near side lower gear casing (9622) |

|

| Off side lower gear casing (9622) |

|

| The bottom plate goes here |

|

| Definitely Crankcase oil required! |

|

| ...Left.... |

|

| ...Right and... |

|

| ...Centre! |

|

| And who's idea was it to do a 'Banksy' of a road railer on the RH window? |

|

| Engine BFP in-situ |

|

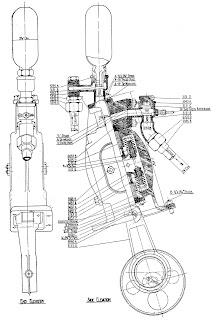

| Part cut-away drawing |

|

| Inlet (RH) and outlet (Left centre)valves |

|

| Inlet valve to the right Outlet valve below the 'bulb' |

|

| Cap on inlet valve chamber |

|

| Cap removed to show inner valve cap |

|

| Inner valve cap removed to show the valve itself on its seat |

|

| Valve removed to show its seat |

|

| Valve itself showing a clean surface |

|

| Valve seat in reasonable condition but would benefit from regrinding |

|

| 'Bulb' instead of cap on valve body |

|

| Base of 'bulb' (just about) showing valve internals |

|

| Valve on seat with washer on top |

|

| Valve on seat with washer removed |

|

| Valve removed with washer in place on top |

|

| Valve seat slightly corroded (green) and needing improvement by regrinding |

|

| Looking better already - all four boiler support areas are visible |

|

| Grubby looking thing! |

|

| Alternative view |

|

| With mounting flange and whistle-mounting elbow |

|

| Whistle valve roof-mounted in Isebrook |

|

| Whistle valve roof-mounted in William |

|

| Front-mounted whistle (the valve is inside) |

|

| Functional Parts |

|

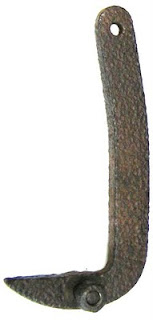

| Conical valve (not to scale!) |

|

| Valve seat inside end of valve body |

|

| Spring and retainer which screws into the end of the valve body |

|

| Rod (not much more to say on this!) |

|

| Operating lever |

|

| Condensate drain |

|

| Note the elegant MDF cab front substitute and supporting clothes' peg! |

|

| Tall thin whistle 1 |

|

| Tall thin whistle 2 |

|

| William's proud possession |

|

| Clearly, it once had a sticky label attached |

|

| Gun-metal mounting and steam inlet to the left |

|

| It's such a simple, passive device, I'm sure I could have made one! |

|

| Cap machined from solid gun-metal |

|

| Shiny and clean as a whistle! |