|

| Boiler Pressure Gauge on cab front |

|

| 60 psi (ish)! |

Have a listen to this (visually not very interesting) video clip:

Streuth! I think it's going to work!

|

| Boiler Pressure Gauge on cab front |

|

| 60 psi (ish)! |

|

| Snug fit around the inlet pipes from this side |

|

| Air conditioned this side! |

|

| October 2014 |

|

| March 2015 |

|

| Boiler Top Cover with Sides fitted |

|

| Cladding Plates |

|

| Start of the Boiler Top Cover assembly |

|

| Space getting tighter |

|

| Ta Da! Flaps Open... |

|

| ...Flaps Closed |

|

| Flap Open... |

|

| ...Flap Closed (or was it the other way round?) |

|

| The white dot is the end of the alignment tool's threaded rod and slightly to the right (in the photo) |

|

| Tubes all parallel to the strap between |

|

| The complete assembly in place (1) |

|

| The complete assembly in place (2) |

|

| View from the inside |

|

| View from the outside |

|

| It's come a long way! |

|

| Nozzles showing machined flat area around each nozzle orifice |

|

| Threaded rod and alignment foot |

|

| Alignment foot with ledge to fit into nozzle orifice |

|

| Number One Tube in place |

|

| Numbers One & Two |

|

| Numbers One, Two & Three |

|

| Numbers One to Four all in place |

|

| View from Above |

|

| Exhaust Steam Pipe to Numbers Three & Four Tubes |

|

| First Heat Shield around numbers One & Two Tubes |

|

| Progress on top of the boiler |

|

| Looking towards the rear, the first casting is held by the strap |

|

| Casting moved above the final location |

|

| Not all is perfect |

|

| Extra cut-away to accommodate the nut |

|

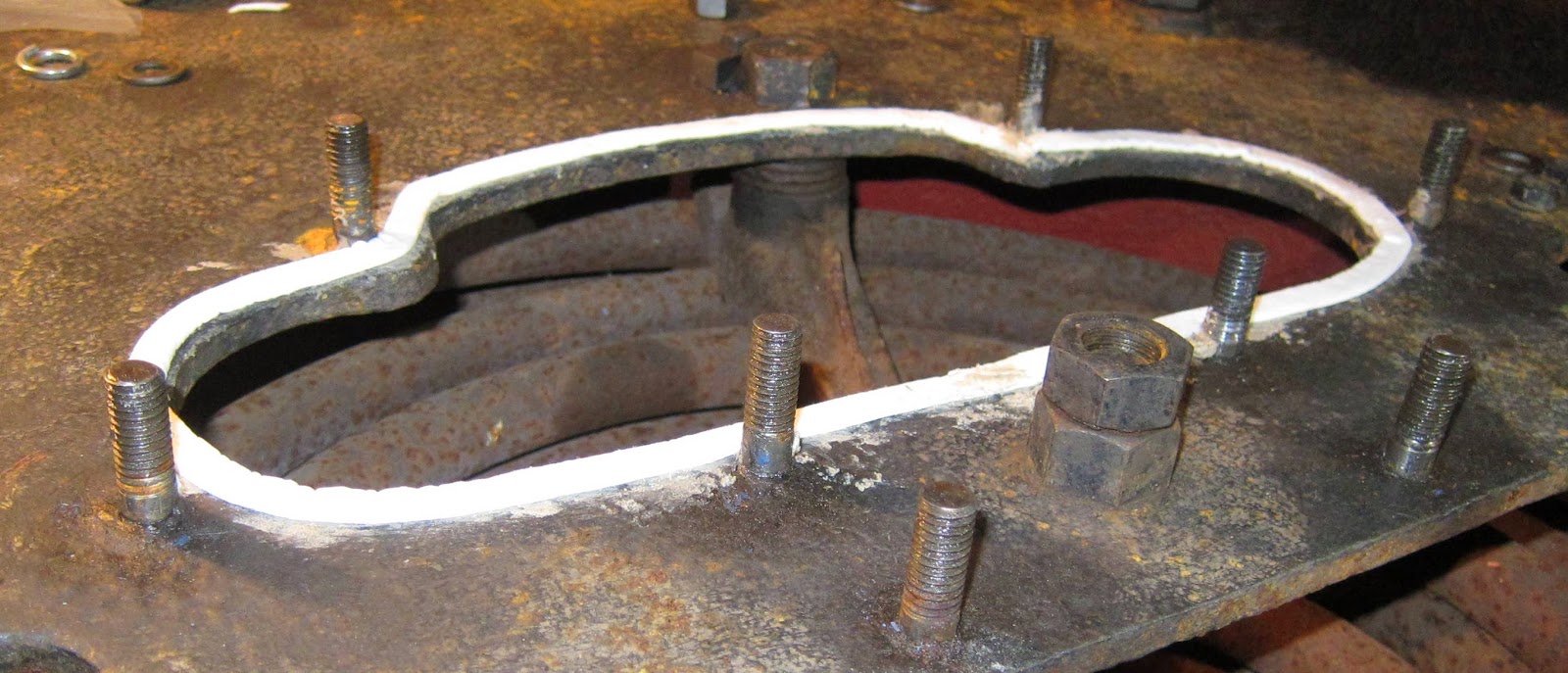

| Ceramic 'felt' seal around the chimney base |

|

| Casting fully seated (1) |

|

| Casting fully seated (2) |

|

| Both castings in place |

|

| RHS Bifurcating exhaust pipe fitted |

|

| View down through to the superheater showing the blast nozzles (My boots were clean at the start of the day!) |

|

| Inside cab (a long time ago) (Photographer unknown. If you claim to own this photo, please leave me a comment). |

|

| Original condition showing the rusty edges |

|

| Close up of top/side join |

|

| No better from the inside |

|

| Half top cover after deconstruction |

|

| Close up, better than it was |

|

| After a coat of red oxide primer |

|

| A Sinking Feeling |

|

| Another Sinking Feeling |

|

| And Yet Another |

|

| Space between the old chimney bases |