'Nutty' is one of a peculiar breed of specialised locomotives that Sentinel made in the 1920s for brickworks use. Their prime requirement was to be very squat in height; very, very squat (5'2" in fact)!

|

Nutty lookalike - Works number 7243 built in 1928

(Photo from Sentinel Drivers' Club collection) |

Built as works number 7701 in 1929 to a 2' 11" gauge, Nutty was one of about five constructed using steam waggon components.

In order to reduce the height as much as possible, the engine was mounted horizontally and the boiler very near to the ground. It also made driving a remarkably intimate experience!

|

No room for foot-plate passengers!

(Photo from SDC collection) |

Neither of the above photos are actually Nutty; however, the next one certainly is.

|

Nutty in August 1971 at the Welshpool & Llanfair Light Railway

(Photo SDC collection) |

The inner workings are clearly visible if you click to enlarge the picture.

I became aware of Nutty through conversations with curators of the Narrow Gauge Railway Museum in Tywyn, Gwynedd, at the terminus of the Talyllyn Railway (where I can be found volunteering on occasions). Nutty is actually owned by the NGRM but it never seems to be found anywhere near the museum!

Although originally built to a gauge of 2'11", it was re-gauged to 2'6" some years ago and it ran on the Welshpool and Llanfair Light Railway for a while. Since that time, I do not know exactly where it has been but I'm led to believe it has spent time at Railworld in Peterborough. In 2012, it made its way to the Leyton Buzzard Railway where it is on display at the Stonehenge Works station.

I visited the LBR on Wednesday 16th July 2014 and was made very welcome indeed. I wanted to poke my digital camera into Nutty's various nooks and crannies to assess its general state. I now have around 170 photos, not all are included here!

|

| Nutty under cover at Stonehenge Works |

|

| Yes, it is chain-driven! |

|

| Side-on view |

|

| Cab internals showing the boiler |

|

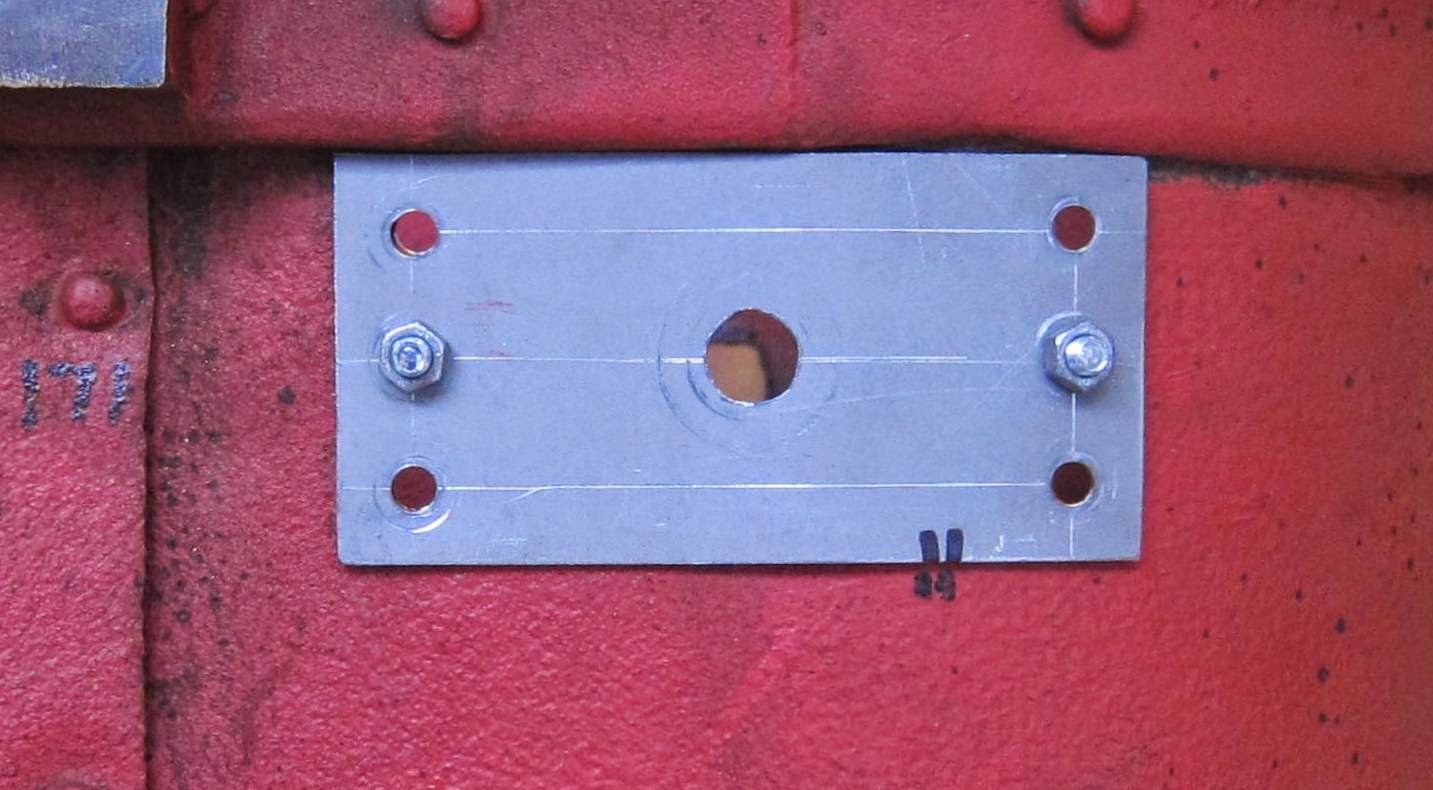

| 'Under the bonnet' view showing the engine beneath the water tank |

|

| Engine, water tank and boiler feed pump |

|

| Bijou accommodation for the driver! |

There are clearly a number of components missing and regrettably I omitted to enquire if they existed. However, it was a good day out and many queries answered as to the construction of this strange locomotive.

Now who volunteers to restore Nutty, reduce the gauge by another 3" and run it on the Talyllyn railway?

April 2024: I've been asked for an assembly drawing of Nutty for modelling purposes. Regrettably this request came about a year ago so please accept my apologies for not monitoring blog comments.

I hope this drawing will help: