|

| Who's the happy-chappy in the passenger seat? |

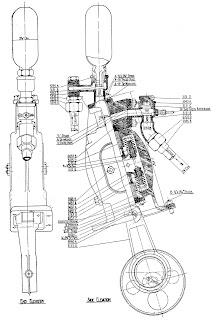

Unlike Sentinel 7109, 8843 has a four cylinder, single acting steam engine (2-stroke) driving the rear wheels via a shaft and axle-mounted differential. Sentinel Super waggons before the 'S' type had two-cylinder, double-acting engines and were chain driven with the differential as an integral part of the engine's crank-shaft.

I was able to have good explore of 8843 during the day but what caught my attention was the engine ticking over in neutral gear. I'd always thought that steam engines were permanently linked to their driving wheels but here was not the case. I was also interested by the sound of the engine; having my camera with me, I used it to record the engine ticking over. Initially it is in late cut-off (starting), then shortly after it starts, the middle (intermediate speed) cut-off setting is selected then finally the late (fast) cut-off setting. Note how the sound changes before it finally stops. (Also on YouTube).

Listen rather than watch (the paint is already dry!)

Whilst out on an evening trip on the roads around Langport, I was sitting just behind the cab and able to catch the 'bark' from the chimney. This next video clip is of 8843 starting from rest and changing gear (cut-off) as it accelerates. (Also on YouTube).

Listen rather than watch (the paint is still dry!)

What also impressed me was the turn of speed. Although 8843 struggled a bit on the hills, on the flat it had no trouble getting to 40mph or so and apparently it can do quite a lot more! I always thought vehicle were pretty slow in the 1930s; clearly Sentinel had produced an advanced, modern vehicle but still propelled by steam!